MMC 2 INSTALLATION INSTRUCTION MANUAL

TABLE OF CONTENTS:

- SELECTION OF SPEAKER LOCATION

- PAINTING SPEAKER FRAMES

- WALL PREPARATION

- TOP FRAME INSTALLATION

- ATTACHING BOTTOM FRAME TO SPEAKER

- BOTTOM FRAME ATTACHMENT TO WALL

- FINAL SPEAKER INSTALLATION

- CAUTIONS

- HOOKUP

- SPEAKER ANGLE ADJUSTMENT

- PHASING

- BASS MANAGEMENT AND PROCESSOR SETTINGS

- TWEETER LEVEL CONTROL

With a little experience, one person can install an MMC 2. However, for the first time, it is recommended that an assistant help with steps D and E of the installation.

-

SELECTION OF SPEAKER LOCATION

Before a permanent installation is begun, we highly recommend purchasing the $30 pair Disposable Speaker Stand Kit to determine if the selected location gives the desired audio performance for the MMC 2s before the first holes are drilled. These mobile wall stands allow the speakers to be easily moved around the room until a permanent position is located. A set of mounting brackets are included with the MMC 2 speaker panels for placement of the speaker panels on the Disposable Speaker Stands.

Because the MMC 2 can used for any channel in a home theater or music system (including as a center channel), and because rooms conditions vary greatly, specific and detailed instructions are not practical. However, there are general guidelines to follow.

Avoid corners. Choose a placement that will position the MMC 2 as far from a corner as possible - preferably more than 3 or 4 feet and the further, the better. We want you to be a satisfied customer and this is a critical issue for good sound. This is especially important for the front channels. Rear channels play a lesser role and more liberties can be taken with the rear channels.

Choose a placement that will allow the bottom of the MMC 2 to be approximately 26 inches from the floor for proper high frequency dispersion when you are sitting or standing.

To help determine the front of the MMC 2, the quasi ribbon foil can be seen through the fabric on the front of the speaker. The speakers should be mounted so that the front of the speakers are on axis with the listener.

CAUTION- Using a level, check to see if the walls are within building code for plumb (vertical to a level floor). If the walls are too far out of plumb, the speakers may not open or close.

-

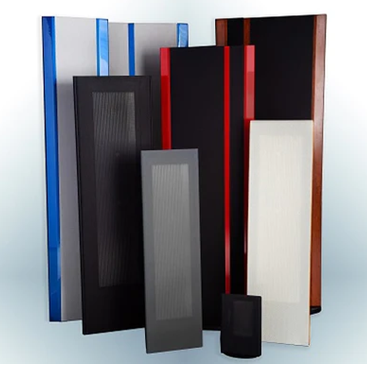

PAINTING SPEAKER FRAMES

Many customers will want to paint the top and bottom molding to match their decor. The top and bottom frames can be ordered with a primer coat. We recommend Krylon spray can paint.

- Mask off hardware in the speaker frames to prevent paint from fouling mechanical parts. Using a very fine steel wool or sandpaper, lightly sand the primer surface to remove any possible contaminants from oily fingers, etc.

- Spray 4 or 5 light coats, allowing drying time to prevent runs in the paint and for a smooth finish. Sand with fine 600 sandpaper between coats for an extra-smooth finish.

- Spray a coat of Krylon clear coat (gloss or satin) to protect the finish.

- Install the speaker trim in the edge of the speaker with a rubber mallet. (Masking tape over the trim will help prevent marring of the finish from the rubber mallet.)

- Install 3/4 inch, 18 ga. brads in the speaker trim to secure the trim.

-

TIPS FROM THE PROS FOR DO-IT-YOURSELFERS

- To run a speaker wire into a wall and out another hole at the bottom, insert a fine steel chain in the top hole that is the length needed to reach the junction box. Use a magnet at the junction box to locate the steel chain. The steel chain will be used to pull the speaker wires through the wall.

- In some cases, it is not practical to route the wires in the wall. A hide-a-cord channel can be used to route the motor wires on the wall down to the lower frame. When the speakers are closed, the hide-a-cord strip is not visible. From the bottom frame to the baseboard, the easiest options are flat speaker wire which can be painted or hide-a-cord channels. Note, the hide-a-cord channels must be low profile to allow the MMC 2 to close completely.

- For the motor and speaker wires to have clearance between the top and bottom frames and the wall, it is necessary to route a small groove on the back of frames.

- A low voltage junction box at the baseboard or a convenient location, is highly recommended.

WALL PREPARATION

- Position the hardboard template against the wall approx. 26" from the floor where the speaker is to be located. Locate the speaker between studs whenever possible. Mark the wall using the upper right corner hole of the template. Set the template aside.

- Drill a 1/4" dia. hole in that location.

- Hold the template against the wall and insert a 1/4" dia. dowel in the hole, leaving 1/4" exposed. See Fig. 1.

- Level the template by placing a level on the top or side of the template. See Fig. 2. CAUTION- Take great care to ensure that the wall is plumb (vertical) and the template is level before drilling the holes. The speakers will not close or open if severely out of plum or level. As an additional precaution, tape the template into position once the template is level--and recheck the level. Misaligned holes are a SERIOUS problem and will require starting over with the installation in a different location.

- Drill a 1/4" dia. hole in the upper left corner of the template. Insert a 1/4" dia. dowel in this hole. Maintaining the template in a level position, drill a second hole in the bottom MIDDLE hole and install a dowel. Now, the template will hang unassisted.

- CAUTION- Double-check to be sure that the template is level. The 4 corner holes are hyper-critical. Once they are drilled, there is very little adjustment that can be done to correct misalignment of the motor mounts. The center top and bottom holes are access holes and are not critical to proper alignment.

- Install (4) sheet rock anchors in the outermost (4) holes. Center holes are for wire feed only. Plastic sheet rock anchors are provided with the speakers. If these are used, the 1/4 inch hole must be enlarged to 5/16 inch. Insert the plastic sheet rock anchors flush with the wall.

- Install (4) #8 x 1-1/2" screws into the sheet rock anchors with approximately 3/16 inch clearance from the wall. USE HAND TOOLS ONLY. NO POWER TOOLS!

- Install painter's tape on the wall above the location of the top frame to prevent marring of the wall while installing the top frame.

Fig. 1

Fig. 1

Fig. 2

Fig. 2

-

TOP FRAME INSTALLATION

- Thread motor wires through the 1/4" dia. center hole and attach the top frame using keyholes on the back of the top frame. If necessary, adjust the screw height to insure a snug fit of the top motor frame to the wall. See Fig. 3 & 4.

Fig. 3

Fig. 3

Fig. 4

Fig. 4

-

ATTACHING BOTTOM FRAME TO SPEAKER

- Caution-- Do not rest the weight of the speaker panel on the speaker wires. Under extreme force, the steel tube could cut through the insulation.

- Lay the speaker on a table with the bottom extending about 12" over the edge of the table.

- Thread the speaker wires through the bottom frame and insert the bottom pin of the speaker into the pivot hole of the bottom frame. See Fig. 5 & 6.

Fig. 5

Fig. 5

Fig. 6

Fig. 6

-

BOTTOM FRAME ATTACHMENT TO WALL

- While keeping the bottom frame and speaker together, take the speaker to the wall for installation. See Fig. 7.

- Feed the speaker wire through the 1/4" dia. bottom center hole and attach the lower frame to the wall using the keyholes on the back of the bottom frame. See Fig. 8 & 9.

Fig. 7

Fig. 7

Fig. 8

Fig. 8

Fig. 9

Fig. 9

-

FINAL SPEAKER INSTALLATION

Many of the adjustments and installation are much easier with the aid of an LED headlamp.

The final step is the most difficult (and may require the help of an assistant). Slightly raise the top frame to allow clearance for the pin on the top of the speaker wheel to clear the top frame when it will be moved into position. See Fig. 10. Slide the motor assembly (and drive wheel) back with your thumb (See Fig. 10) to allow clearance between the two wheels so that the shaft on the speaker can be inserted into the top frame pivot hole. See Fig. 10.

Fig. 10

Fig. 10

-

Final Adjustments

- Helpful hint--Ensuring that the panel moves freely or detecting the slight resistance of the Cam/Stop is made easier if the motor assembly and drive wheel is pulled away from the idler wheel. The motor assembly can be held out of the way by attaching a 1 inch-wide piece of duct tape to the entire length of the motor frame. Pull the frame back with the tape under tension and attach the duct tape to the end of the wood frame.

- The top frame must be snug to the wall to prevent accidental dislodging of the top frame. Readjust the top screw heights, if necessary, for a snug fit into the key holes. Before you begin the adjustment, take the precaution of securing the top frame. It will be necessary to lift up on the speaker frame as you make this adjustment. This could result in the top frame coming loose from the wall. Painter's tape can help to prevent the top frame from being pushed upward during the speaker angle adjustment.

- If the top frame were inadvertently knocked off, the speaker could fall, causing damage to the speaker. To install a keeper to prevent this accident, make a mark on the wall at the top of the frame on both ends of the frame. Drill a small hole in the wall the same size as a brad (which has a small head). When the installation is complete. Insert the brads into the holes after completing the installation. The head of the brad will be above the line of sight and will act as a keeper to prevent the top frame from being pushed upward. Use a long nose priers to remove the brad for servicing the speakers.

- Important- The wheels must be properly aligned for FULL contact to ensure that the wheels will not slip during opening or closing. Adjust the wheel height on the speaker with the included allen wrench, if necessary. The help of an assistant will be required to adjust the wheel height. Raise the top frame and, with the help of an assistant, hold the speaker in a vertical position while loosening the set screws to make the height adjustment. Reinstall the shaft into the top frame pivot hole while pulling back the motor assembly to allow for wheel clearance. Slide the loosened wheel up or down on the shaft to have maximum contact with the drive wheel. Tighten the two set screws.

- To confirm that the speaker panel can move freely, pull the drive motor assembly back with your thumb so that the drive wheel is disengaged from the idler wheel. Slowly move the speaker panel through it's 180 degree range of motion to check for excessive resistance. If the MMC 2 is installed correctly for plumb and level (so that the motor is not pushing the panel "uphill" upon opening or closing), and the speaker panel is free to move without undue resistance, our testing and field experience has shown that the motor and drive wheels will reliably open and close the MMC 2.

- The template provides very accurate placement of the top and bottom frame holes. However, mistakes can happen. In the event the gap between the top or bottom frame and the speaker is not correct, a modification is possible to allow for some adjustment of the gap spacing. The frame key hole slot can be lengthened with a file or Dremel tool to allow the frame to be lowered on one side. However, the head of the pan-head screw will impact on the interior portion of the frame. It is necessary to modify the screw with a file or grinder. First, make certain that the screw to be modified is adjusted to the correct amount to ensure a tight fit of the frame. Mark the top portion of the screw head with a permanent marker and remove the screw. Grind or file the marked portion of the screw and reinstall.

-

HOOKUP

Connect the positive (red) speaker wire to the MMC 2 white and red wire. We recommend that the connection to the speaker wire be soldered with shrink tubing for electrical insulation. Check for correct phasing before making a permanent connection.

-

In case you missed it in the manual-

A few hints when installing the Controller/Power Supply for the MMC 2-- 1) Be sure to set the motor timer for approximately 2 seconds longer than is needed to fully open or close the speaker panels. 2) Use equal length wires to each motor so the voltage drop is the same to achieve uniform motor speed (or adjust the relative speed with resistors. 3) Set the motor voltage (speed) as slow as practical.

-

SPEAKER ANGLE ADJUSTMENT

Some of the adjustments below are easier if the motor is pulled back using a strip of duct tape as described above in Final Speaker Installation.

For the best sound, the MMC 2 should be angled so that the panel is on-axis with the listener with a minimum distance from the wall of 30 degrees. (Use of the MMC 2 as a dual center channel speaker requires slightly different adjustments. Contact Magnepan for dual center speaker installations).

This adjustment can be challenging on your first attempt. The figure, below, shows the concept of the Cam/Stop. It is not an actual drawing of the parts, but, the visualization of the design may be helpful to make the adjustment.

CAUTION-- Before you begin the adjustment, take the precaution of securing the top frame. It will be necessary to lift up on the speaker frame as you make this adjustment. This could result in the top frame coming loose from the wall and falling. Painter's tape can help to prevent the top frame from being pushed upward during the speaker angle adjustment.

Fig. ____

Fig. ____

Pull the MMC 2 out until you feel the slight resistance of the Cam/Stop. (Note- If you do not feel the resistance of the Cam/Stop, the Cam has been rotated 180 degrees and the Cam must be rotated further until the Cam and Stop intersect.) Insert the long 5/64 inch allen wrench into the Cam/Stop at the bottom of the speaker as shown in Fig. 1 and 2 below and loosen the allen screw. Rotate the MMC 2 to the desired position as shown in Fig. 3 and 4 while holding the Cam/Stop stationary. It is necessary to raise the MMC 2 slightly to remove the weight of the speaker off of the Cam/Stop so that the speaker can be rotated independently of the Cam/Stop.Tighten the allen screw. If the Cam/Stop moves in the process of moving the MMC 2, the angle will be wrong. In that case, another adjustment will be necessary.

Lift the speaker panel as high as possible to expose the allen screws. Insert the long 5/64 inch allen wrench into the allen screws in the Cam/Stop at the bottom of the speaker as shown in Fig. 1 and 2. Loosen all but one of the allen screws (Your cam may have 2 or 3 allen screws). Next, pull the MMC 2 out until you feel the slight resistance of the Cam/Stop. (Note- If you do not feel the resistance of the Cam/Stop, the Cam has been rotated 180 degrees and the Cam must be rotated further until the Cam and Stop intersect.) Maintain the speaker panel at the position where the Stop has hit the Cam. Lift the speaker panel as high as possible to gain access to the allen screws. Insert the long 5/64 inch allen wrench into one tightened allen scew in the Cam/Stop. Loosen the allen screw and use the allen wrench to hold the cam at the same position while you rotate the MMC 2 to the desired position. It is necessary to keep the weight of the speaker panel off of the Cam/Stop so that the speaker can be rotated independently of the Cam/Stop. Tighten the allen screw. Invariably, the Cam/Stop will move slightly in the process of moving the speaker panel and the angle will be wrong. In that case, another adjustment will be necessary. The last step is to check the panel angle by using the Controller/Power Supply which may not be the exactly the same as the manual setting.

The angle of the MMC 2 should never be set for less than 30 degrees for optimum sound.

Setting stop in closed position-- A nylon screw is included with the MMC 2 to act as a stop so that the MMC 2 can be adjusted to be parallel with the wall in the closed position. The screw hole is located at the bottom inside edge of the MMC 2. To ensure that the nylon screw will not loosen, wrap Teflon plumber's tape on the threads or a drop of blue Loctite or score the threads lengthwise.

Fig. 11

Fig. 11

Fig. 12

Fig. 12

Fig. 13

Fig. 13

Fig. 14

Fig. 14

-

Phasing

- Correct phasing between a "small" speaker, like the MMC 2, and the Bass Panel is much more difficult to detect than an out-of-phase condition between left and right speakers. The ear/brain is less sensitive to phase shift problems at lower frequencies and therefore, making it more difficult to detect. However, an out-of-phase condition between the MMC 2s and the Bass Panel will result in a perceived frequency imbalance. A "suckout" in the midbass due to an out-of-phase condition will subjectively make the MMC 2s seem "bright" with excessive high frequencies.

- The manufacturer of a full-range speaker gives considerable attention to achieving correct phasing between the midrange and bass drivers. To get the full benefit of your high performance MMC 2s, we suggest that you get the help of your dealer or a technician to ensure that the phasing between the MMC 2s and your woofer is correct.

- A Magnepan "Shaped" Pink Noise CD Test Disk is included with your MMC 2s to assist in the proper phasing between the MMC 2s and your Bass Panel. The pink noise CD is "shaped" with a 9 db peak at 80-100 Hz. This aids in the detection of an out-of-phase condition. This peak in the midbass focuses the attention of the listener on this area of the frequency response. When the MMC 2s are out of phase with the Bass Panel, this peak will be reduced in level. Place the Magneplanar Bass Panel (or subwoofer) next to the MMC 2s (It is much easier to detect an out-of-phase condition when the "small" speaker is physically next to the Bass Panel.)

- A technique which can aid in determining if the phase is correct is by leaning over and positioning your head equi-distance between the Magneplanar Bass Panel and the "small" Magneplanar as shown in Bass Panel manual. The left and right ears are equi-distance to the respective speakers. High frequencies will appear to be up and low frequencies will appear to be down. The 90-100 Hz peak, if in phase, will appear to be in the middle (and louder). Since the Magneplanar Bass Panel is a dipole, the rear wave is out of phase with the front wave. To reverse the phase for a phase test, simple turn the Maggie Bass Panel around.

- However, depending on where the Bass Panel is placed, it is possible for the MMC 2s and the Bass Panel to be 90 degrees out of phase with the Bass Panel. This will result in little or no difference in loudness of the peak as the phase is changed. Usually, this means that the woofer is not placed at the correct distance relative to the MMC 2s. Many powered woofers have continuous phase shift adjustments to correct this problem without moving the woofer, although changing the location of the woofer is the preferred solution.

-

Bass Management and Processor Settings

- The MMC 2 is a "small" speaker with limited midbass response. A high-pass filter is required for the operation of the MMC 2s to roll off the bass frequencies to the MMC 2s. The Magneplanar XO 2 passive crossover can be used with the MMC 2s or if a processor is being used, the processor can be set for "small" speaker.

- The lower frequency response of the MMC 2 depends, to a large degree, on the room acoustics and where the MMC 2s are used in the room. For example, a front wall placement of the MMC 2s will result in less midbass and therefore require a higher crossover point. A side wall placement of the MMC 2s in a shoe-boxed shaped room (when placed about 4 feet or more from the front wall) will give the deepest midbass response. Crossover points may vary from 100 Hz to as high as 160-200 Hz, depending on all the variables.

-

Tweeter Level Control

- A rocker switch is located on the back of the speaker near the top (in the crossover region). Depressing the switch to the right will give maximum high frequencies. Depressing the switch to the left will reduce the high frequencies with a 1 ohm resistor.

Revised- 1-16-13